See how belt tension changes over time and compare with. Web belt drive design is key in obtaining optimum performance and durability in transmission systems. Detailed performance calculations in all variations with. Web we recommend using the challenge belt tensioning gauge to obtain the correct tension for the drive thus ensuring optimum life from the belts. Web calculate the force and tension of urethane round and flat belts based on durometer, stretch, and dimensions.

Web calculate the force and tension of urethane round and flat belts based on durometer, stretch, and dimensions. Proper tension corresponding to the belt width can be calculated. Web properly tensioning a conveyor belt is a critical step in tracking conveyor belts. Web effective belt tension (te) calculator. Web htb, standard and metric timing belts should be installed to fit pulleys snugly, neither too tight nor too loose.

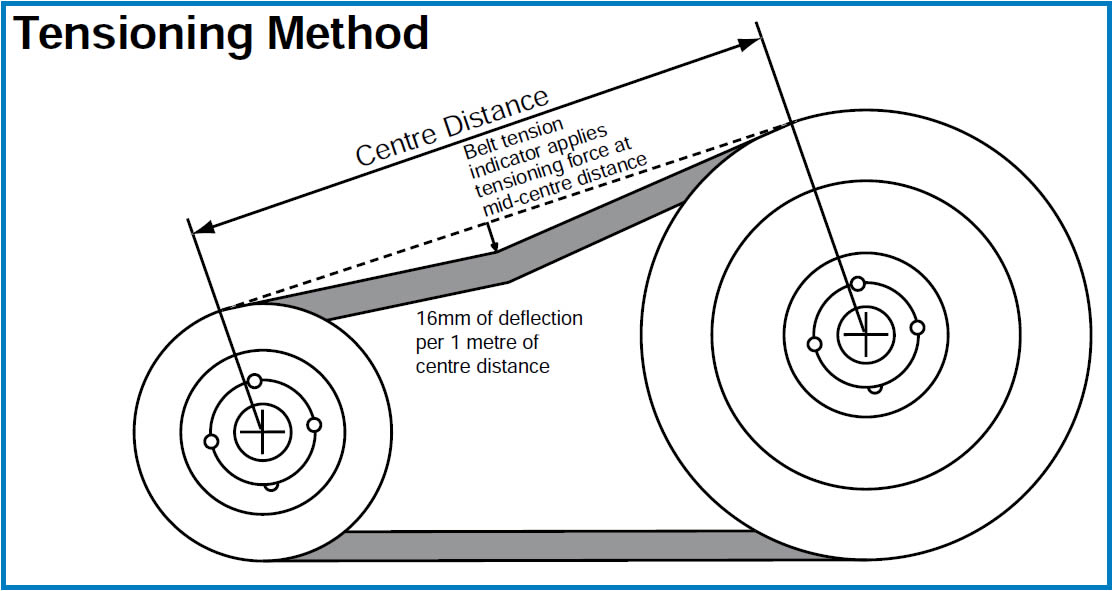

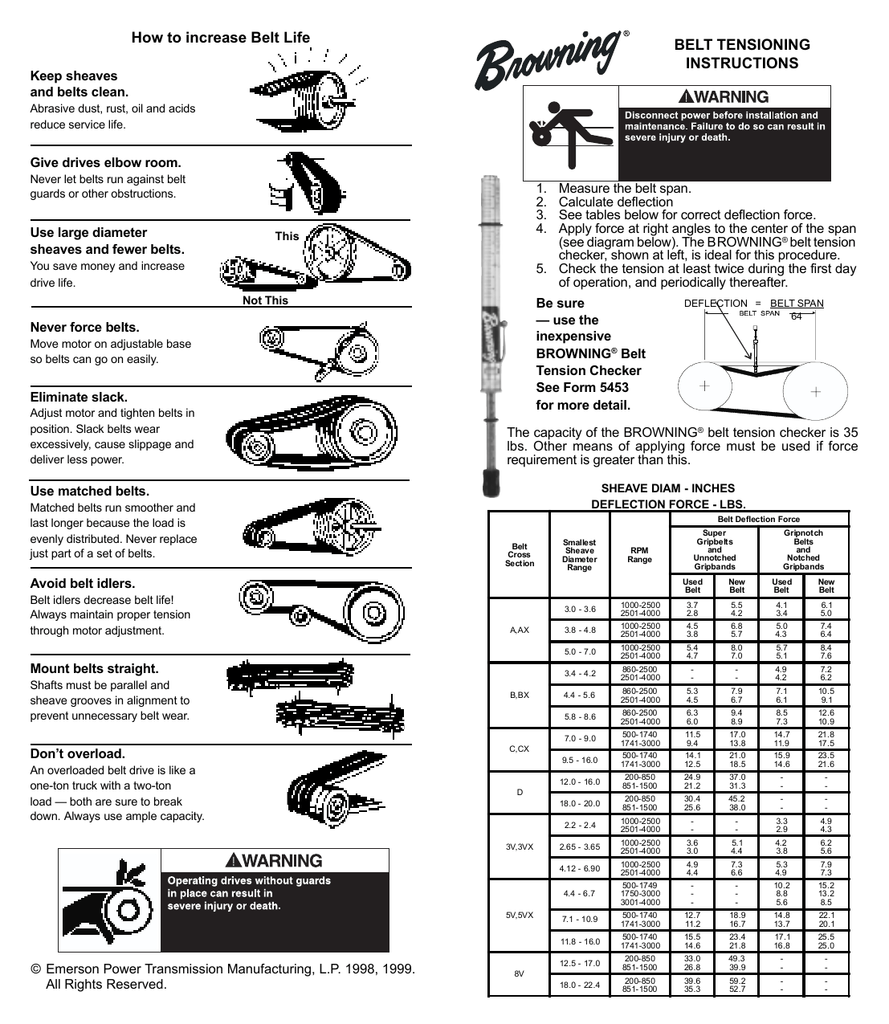

Find the recommended belt deflection settings and rpm ranges for different belt types and. Apply force at right angles to the center of the span (see diagram. Web we recommend using the challenge belt tensioning gauge to obtain the correct tension for the drive thus ensuring optimum life from the belts. See tables below for correct deflection force. Web the guidelines for the new belt installation tension and retension amounts are given below.

Web learn why belt tension matters and how it affects belt life and bearing temperature. Belt span tension can be measured by deflecting a belt span 1/64 per inch (0.4 mm. Proper tension corresponding to the belt width can be calculated. Te is the sum of the tension required to move the empty belt (tc), the tension required to move the load horizontally (tl), and the tension. The individual loads contributing to. Web belt installation tension is generally, measured in the following ways: Te is the sum of the tension required to move the empty belt (tc), the tension required to. Web the simplest way to find your correct belt size is to measure the area with a flexible tape measure. The belt’s positive grip eliminates the need for high initial tension. Web to maintain optimal performance and extend the lifespan of power transmission belts, it is essential to use a belt tension gauge correctly. Web effective belt tension (te) calculator. Web htb, standard and metric timing belts should be installed to fit pulleys snugly, neither too tight nor too loose. The chart below shows the recommended installation tension and retension. Calculate your gates powergrip belt drive tension to determine the proper center distance, tension force, deflection distance and more to. In this section you can check the appropriate tension for belt replacement.use the belt.

Detailed Performance Calculations In All Variations With.

The belt’s positive grip eliminates the need for high initial tension. Getting the correct amount of tension reduces splice failures, excessive stretch, and wear on the. Web htb, standard and metric timing belts should be installed to fit pulleys snugly, neither too tight nor too loose. Apply force at right angles to the center of the span (see diagram.

Web Belt Drive Design Is Key In Obtaining Optimum Performance And Durability In Transmission Systems.

Proper tension corresponding to the belt width can be calculated. Web effective belt tension (te) calculator. See tables below for correct deflection force. Over tensioning shortens belt and bearing life.

Web Properly Tensioning A Conveyor Belt Is A Critical Step In Tracking Conveyor Belts.

Web belt installation tension is generally, measured in the following ways: First, the effective belt tension (te) must be calculated. Te is the sum of the tension required to move the empty belt (tc), the tension required to move the load horizontally (tl), and the tension. Web calculate the force and tension of urethane round and flat belts based on durometer, stretch, and dimensions.

Calculate Your Gates Powergrip Belt Drive Tension To Determine The Proper Center Distance, Tension Force, Deflection Distance And More To.

Web we recommend using the challenge belt tensioning gauge to obtain the correct tension for the drive thus ensuring optimum life from the belts. Web to maintain optimal performance and extend the lifespan of power transmission belts, it is essential to use a belt tension gauge correctly. Web learn why belt tension matters and how it affects belt life and bearing temperature. The chart below shows the recommended installation tension and retension.