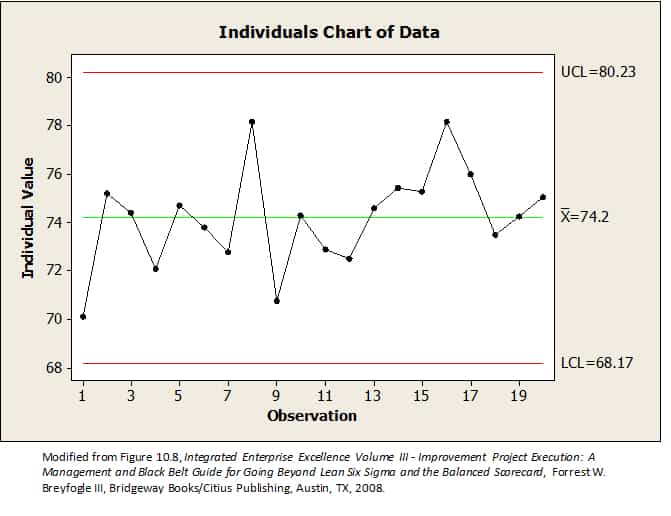

You can start calculating the control limits after five data points. The lower control limit, labelled lcl on the graph, indicates that on this xbar chart, any group of five packages averaging under 41.7503g is an indication that the process is unstable and special cause variation exists. You can specify a lower bound and an upper bound for the control limits. In minitab you can change the lower boundary to requested limit bound. Lower control limit (lcl) upper control limit (ucl) notation.

Lcl line shows the lower control limit. This newsletter has examined when to calculate control limits when you first start a control chart. The lower control limit, labelled lcl on the graph, indicates that on this xbar chart, any group of five packages averaging under 41.7503g is an indication that the process is unstable and special cause variation exists. The control chart xmr consists of two charts: Upper control limit (ucl) notation.

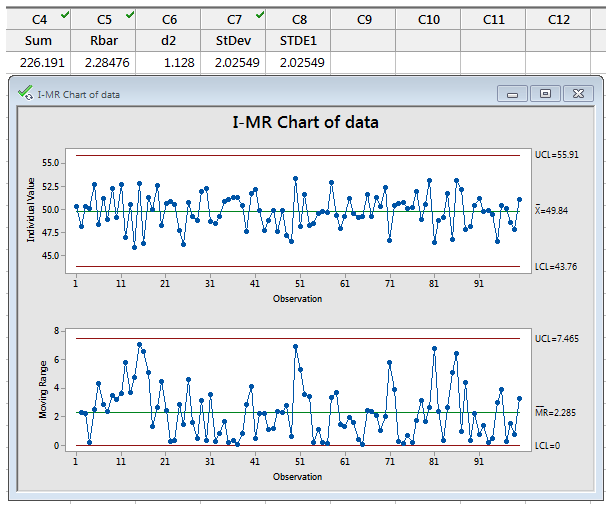

That is, anything unusual in the mr chart is also apparent in the i chart. If minitab plots the upper and lower control limits (ucl and lcl). Where mri is the moving. The control chart xmr consists of two charts: Lower control limit (lcl) the lcl is the greater of the following:

Lower control limit (lcl) upper control limit (ucl) notation. The control chart xmr consists of two charts: Calculate the control limits for the moving range chart 1. If the calculated control limit is farther from the center line than the value that you specify, minitab displays the bound. 1) the mr chart provides redundant information and is not necessary. The average moving range, , of length w is given by. Upper control limit (ucl) notation. Yes, minitab did produce a negative lcl, and zero is the lowest possible (we are measuring units returned for warranty credit). Determining whether a process is stable and ready to be improved. Lcl line shows the lower control limit. Individuals and moving range chart. There are seven main types of control charts (c, p, u, np, individual moving range xmr, xbarr and xbars.) plus there are many more variations for special circumstances. To calculate the upper control limit, multiply the average moving range, , by. Another option is to use. As we know sometimes when we calculate the natural process limits, the lower limit is negative.

This Is Then Where You Get A Negative Control Limit.

In some measures, that’s not a practical value, like in the example below. Select the method or formula of your choice. 95% or 99% of data should fall within ucl and lcl. When you change an unstable process,.

Lower Control Limit (Lcl) The Lcl Is The Greater Of The Following:

One method is to use the median moving range. 2 best practices when thinking about a lower control limit. As we know sometimes when we calculate the natural process limits, the lower limit is negative. The lower control limit, labelled lcl on the graph, indicates that on this xbar chart, any group of five packages averaging under 41.7503g is an indication that the process is unstable and special cause variation exists.

Determining Whether A Process Is Stable And Ready To Be Improved.

The median moving range is impacted much less by large moving range values than the average. Yes, minitab did produce a negative lcl, and zero is the lowest possible (we are measuring units returned for warranty credit). That is, anything unusual in the mr chart is also apparent in the i chart. If the calculated control limit is farther from the center line than the value that you specify, minitab displays the bound.

Lower Control Limit (Lcl) The Lcl Is The Greater Of The Following:

The control chart xmr consists of two charts: To calculate the upper control limit, multiply the average moving range, , by. Calculate the control limits for the moving range chart 1. Upper control limit (ucl) notation.