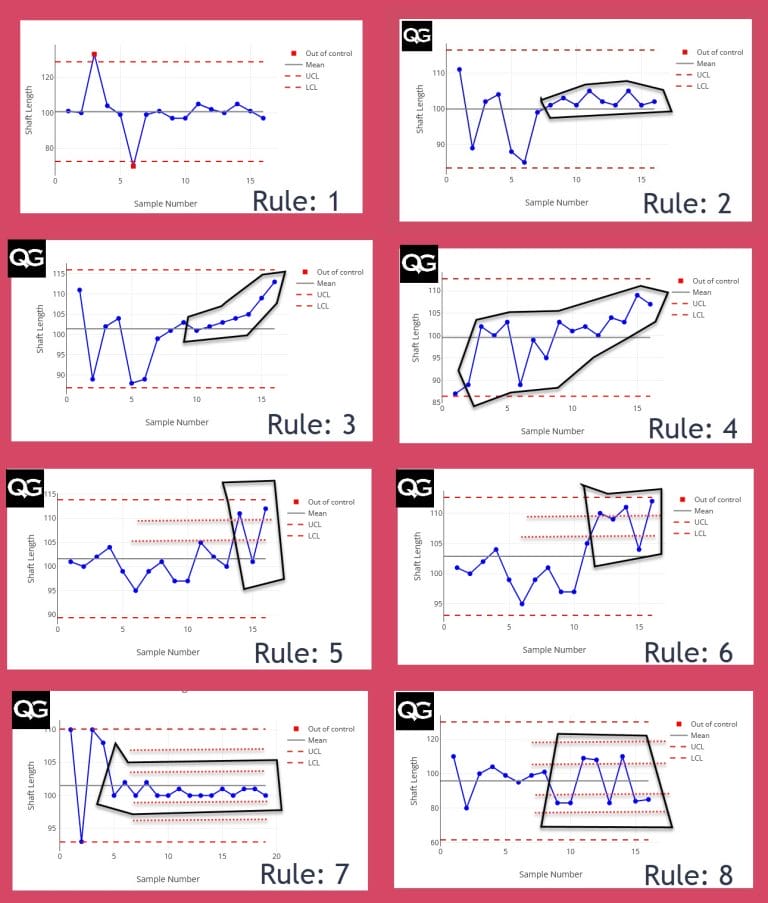

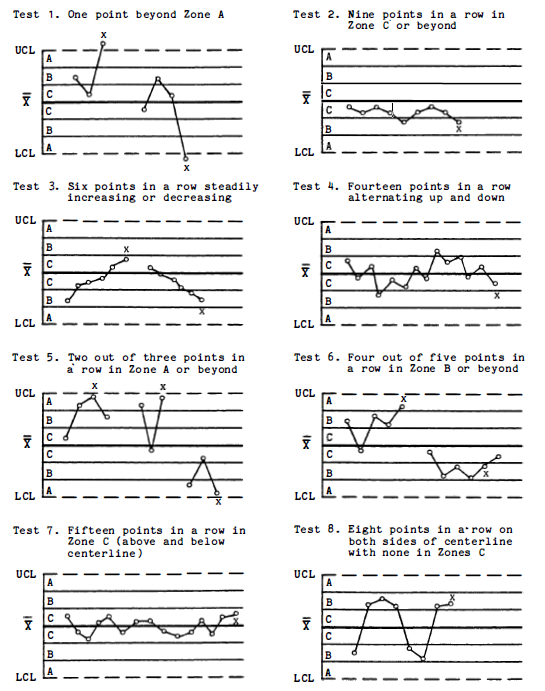

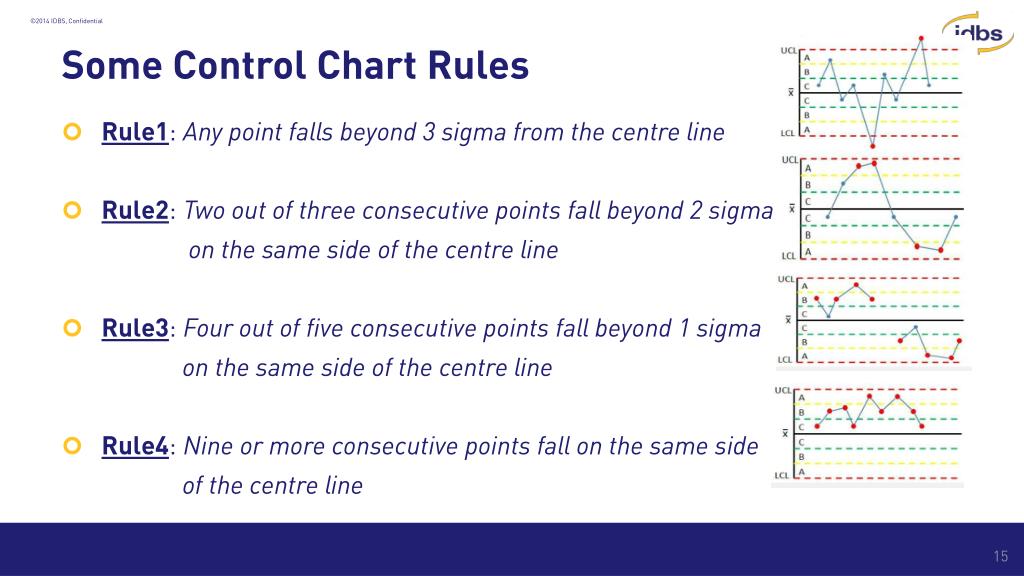

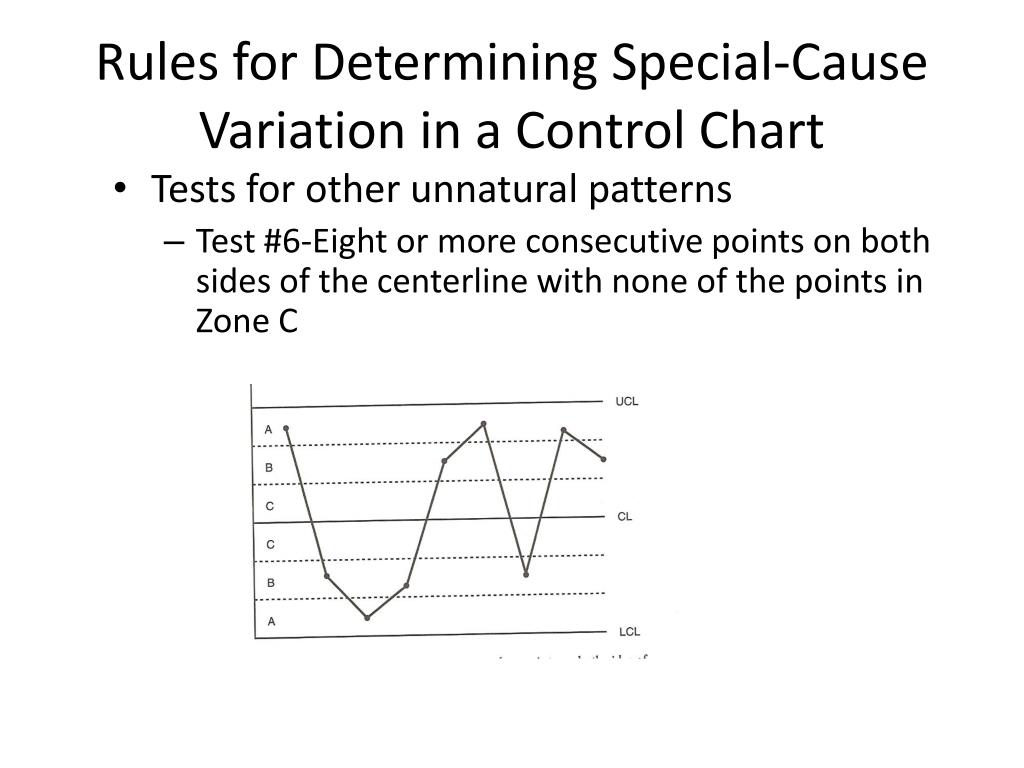

Here are some common control chart rules: One point beyond control limits: Web choose the appropriate control chart for your data. Suitable for small sample sizes. Web this month’s publication examines 8 rules that you can use to help you interpret what your control chart is communicating to you.

Suitable for small sample sizes. Web this month’s publication examines 8 rules that you can use to help you interpret what your control chart is communicating to you. Web the most common types are: Web control charts effectively track defects and reduce rework costs by distinguishing normal process variation from abnormal defects. Web control chart rules or guidelines are used to interpret control charts, helping to identify patterns that suggest a process is out of statistical control.

One point beyond control limits: Web choose the appropriate control chart for your data. Used to monitor the mean (average) and range (variability) of a process. Web the descriptions below provide an overview of the different types of control charts to help practitioners identify the best chart for any monitoring situation, followed by a description of the method for using control charts for analysis. Web this month’s publication examines 8 rules that you can use to help you interpret what your control chart is communicating to you.

They help pinpoint when and where defects are being introduced in the production process. Used to monitor the mean (average) and range (variability) of a process. Collect data, construct your chart and analyze the data. Web the most common types are: Web the descriptions below provide an overview of the different types of control charts to help practitioners identify the best chart for any monitoring situation, followed by a description of the method for using control charts for analysis. Here are some common control chart rules: One point beyond control limits: Determine the appropriate time period for collecting and plotting data. Suitable for small sample sizes. Web the following rules can be used to properly interpret control charts: These rules help you identify when the variation on your control chart is no longer random, but forms a pattern that is described by one or more of these eight rules. When one is identified, mark it on the chart and investigate the cause. Web choose the appropriate control chart for your data. Web control charts effectively track defects and reduce rework costs by distinguishing normal process variation from abnormal defects. Web this month’s publication examines 8 rules that you can use to help you interpret what your control chart is communicating to you.

One Point Beyond Control Limits:

Web the most common types are: Here are some common control chart rules: Collect data, construct your chart and analyze the data. Web the following rules can be used to properly interpret control charts:

When One Is Identified, Mark It On The Chart And Investigate The Cause.

Web choose the appropriate control chart for your data. Web the descriptions below provide an overview of the different types of control charts to help practitioners identify the best chart for any monitoring situation, followed by a description of the method for using control charts for analysis. Web control chart rules or guidelines are used to interpret control charts, helping to identify patterns that suggest a process is out of statistical control. Web control charts effectively track defects and reduce rework costs by distinguishing normal process variation from abnormal defects.

These Rules Help You Identify When The Variation On Your Control Chart Is No Longer Random, But Forms A Pattern That Is Described By One Or More Of These Eight Rules.

Used to monitor the mean (average) and range (variability) of a process. They help pinpoint when and where defects are being introduced in the production process. Determine the appropriate time period for collecting and plotting data. Suitable for small sample sizes.