Vacuum to pressures of 350 bar (5000 psi) can be handled dependent upon. Web download a pdf copy of our complete catalog this catalog includes every fitting on our website. Web the most common flare fitting standards in use today are the 45° sae flare, the 37° jic flare, and the 37° an flare. When connected, the flare seats form a seal, while the straight threads provide a mechanical bond. *please note, this catalog is 126 pages so the file may take a minute or two to download depending on your computer speed and.

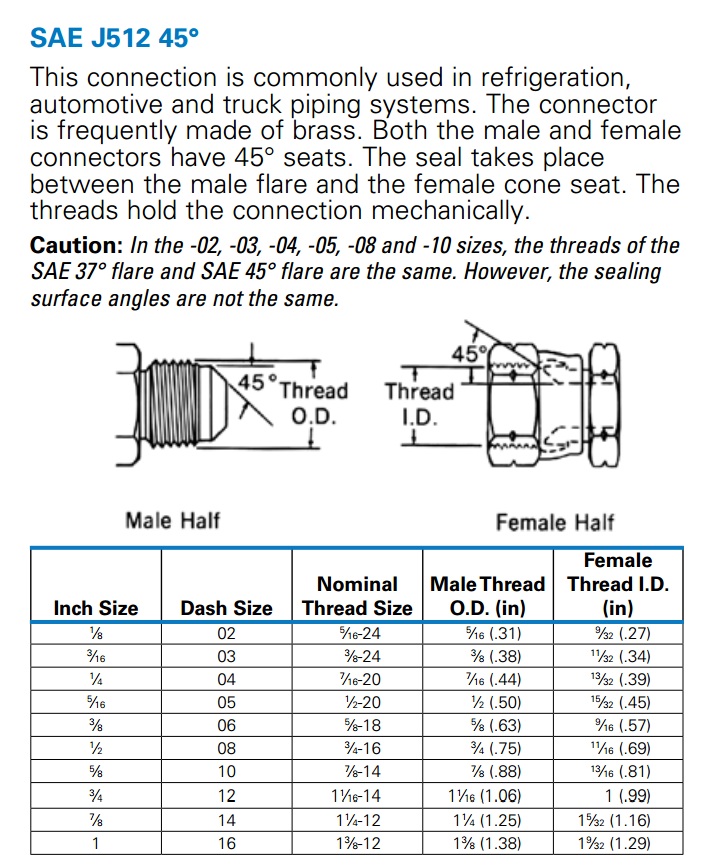

Web after measuring the diameter of your threads, determine their spacing in threads per inch. To get an accurate value, ensure that the thread pitch gauge is fitting well on the threads. Web the most common flare fitting standards in use today are the 45° sae flare, the 37° jic flare, and the 37° an flare. Web these flare sae 45° fittings may be used with copper, brass, aluminium, steel and plastic tube provided an acceptable flare can be generated with the material. Never use a single 45 degree flare with automotive nuts and fittings.

Web check that the flare is the correct profile for the components involved. Web sae thread inverted flare fitting is widely used in automotive systems, the inverted flare connection features a machined male connector with a 42° seat, and a flared male tubing with a 45°seat. Web these flare sae 45° fittings may be used with copper, brass, aluminium, steel and plastic tube provided an acceptable flare can be generated with the material. A 37 degree single flare is acceptable for use in an/jic nuts and fittings with cunifer seamless tubing. Web the most common flare fitting standards in use today are the 45° sae flare, the 37° jic flare, and the 37° an flare.

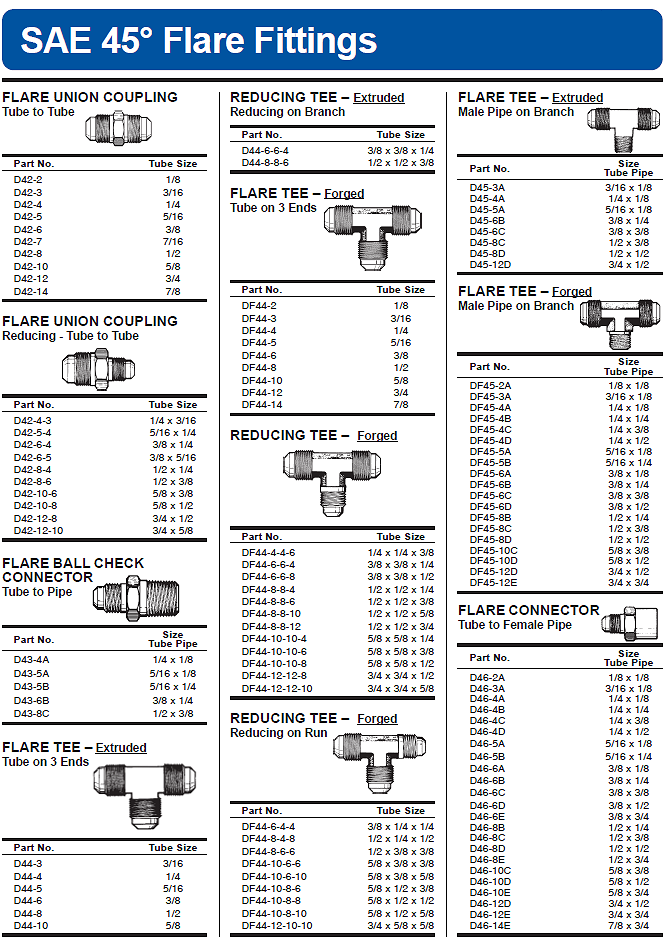

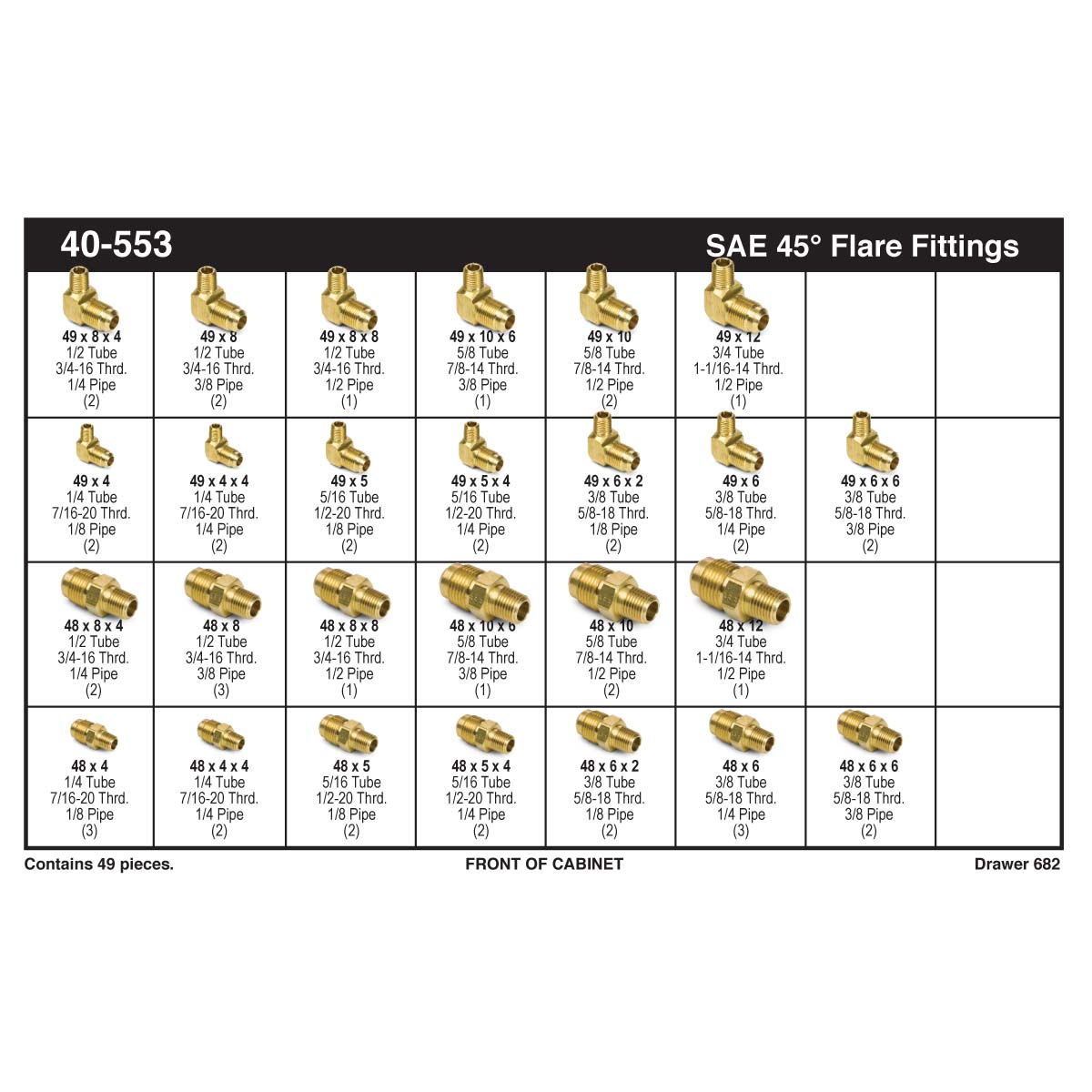

Web jic fittings, commonly used in hydraulic systems, have 37° flare connectors with both male and female parts featuring a 37° flare seat and straight threads. Never use a single 45 degree flare with automotive nuts and fittings. Sae 45° flare connections are commonly used in automotive applications as well as for refrigeration and air conditioning. Web the most common flare fitting standards in use today are the 45° sae flare, the 37° jic flare, and the 37° an flare. Web check that the flare is the correct profile for the components involved. The female side has a 42° seat that provides a sealing surface. When connected, the flare seats form a seal, while the straight threads provide a mechanical bond. Web sae thread inverted flare fitting is widely used in automotive systems, the inverted flare connection features a machined male connector with a 42° seat, and a flared male tubing with a 45°seat. Automotive fittings are always a 45 deg. Web after measuring the diameter of your threads, determine their spacing in threads per inch. *please note, this catalog is 126 pages so the file may take a minute or two to download depending on your computer speed and. Web these flare sae 45° fittings may be used with copper, brass, aluminium, steel and plastic tube provided an acceptable flare can be generated with the material. To get an accurate value, ensure that the thread pitch gauge is fitting well on the threads. Vacuum to pressures of 350 bar (5000 psi) can be handled dependent upon. Web download a pdf copy of our complete catalog this catalog includes every fitting on our website.

Web After Measuring The Diameter Of Your Threads, Determine Their Spacing In Threads Per Inch.

Sae 45° flare connections are commonly used in automotive applications as well as for refrigeration and air conditioning. The female side has a 42° seat that provides a sealing surface. Automotive fittings are always a 45 deg. Web sae thread inverted flare fitting is widely used in automotive systems, the inverted flare connection features a machined male connector with a 42° seat, and a flared male tubing with a 45°seat.

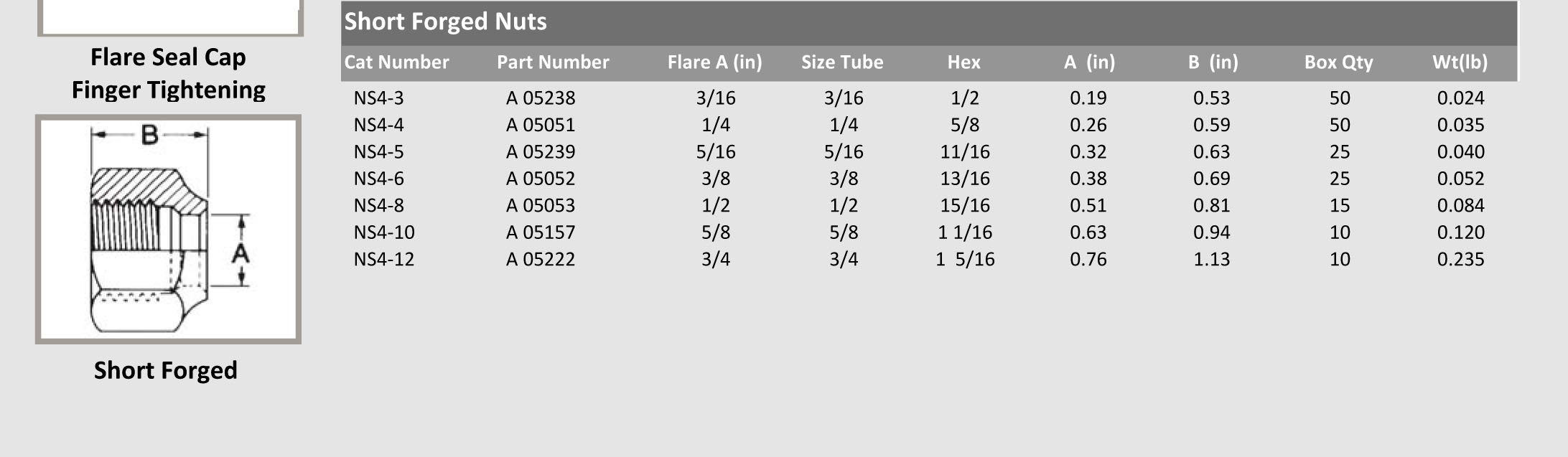

Web These Flare Sae 45° Fittings May Be Used With Copper, Brass, Aluminium, Steel And Plastic Tube Provided An Acceptable Flare Can Be Generated With The Material.

Never use a single 45 degree flare with automotive nuts and fittings. Vacuum to pressures of 350 bar (5000 psi) can be handled dependent upon. To get an accurate value, ensure that the thread pitch gauge is fitting well on the threads. Web check that the flare is the correct profile for the components involved.

Web The Most Common Flare Fitting Standards In Use Today Are The 45° Sae Flare, The 37° Jic Flare, And The 37° An Flare.

Two of the most common types are the jic 37° flare fittings and the sae 45° flare fittings. A 37 degree single flare is acceptable for use in an/jic nuts and fittings with cunifer seamless tubing. Web jic fittings, commonly used in hydraulic systems, have 37° flare connectors with both male and female parts featuring a 37° flare seat and straight threads. Web download a pdf copy of our complete catalog this catalog includes every fitting on our website.

When Connected, The Flare Seats Form A Seal, While The Straight Threads Provide A Mechanical Bond.

*please note, this catalog is 126 pages so the file may take a minute or two to download depending on your computer speed and.