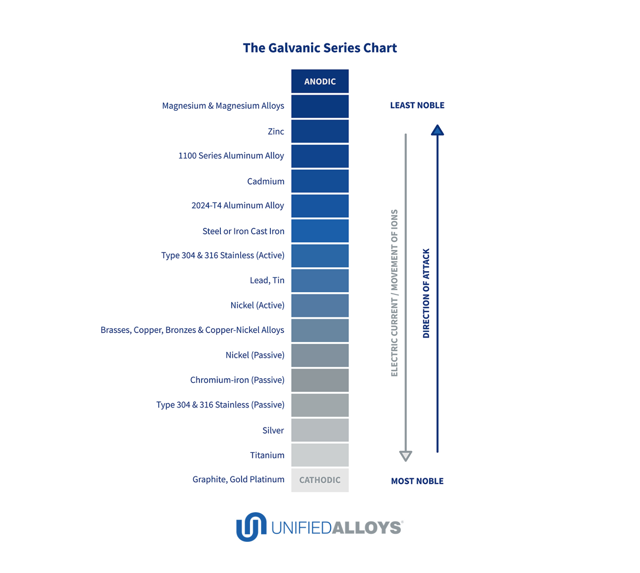

So, for example, choosing zinc on zinc would have the lowest risk for corrosion. We also provide other helpful methods for avoiding galvanic corrosion. Web however, you can completely avoid galvanic corrosion by choosing matching metal anchors. The list begins with the more active (anodic) metal and proceeds down. Web galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte.

The closer together the material are on the chart to the right, the less galvanic action will occur. Web galvanic corrosion is a localised mechanism by which metals can be preferentially corroded. Web however, you can completely avoid galvanic corrosion by choosing matching metal anchors. Web in a galvanic couple, the metal higher in the series (or the smaller) represents the anode, and will corrode preferentially in the environment. The corroded area was machined out and rebuilt with alloy 625 filler metal which is cathodic to the copper nickel piping.

Web by knowing the relationships of the metals in the series, galvanic compatibility can be determined, preventing the possible harmful effects of galvanic corrosion. The small surface area of the active bolts results in an undesirable galvanic couple and they are exhibiting an accelerated corrosion rate. Web the galvanic corrosion table ranks metals from the most “active” to the least active. Web below is a galvanic reaction chart for dissimilar metals. This form of corrosion has the potential to attack junctions of metals, or regions where one construction

The following galvanic table lists metals in the order of their relative activity in seawater environment. The small surface area of the active bolts results in an undesirable galvanic couple and they are exhibiting an accelerated corrosion rate. A typical rule of thumb is that voltage differences of 0.2 volts or more suggest a galvanic corrosion risk. A classification of the different metals and alloys according to this measured potential (see chart below). Web galvanic corrosion undermined the keeper rings, leading to failure and leakage. Web by knowing the relationships of the metals in the series, galvanic compatibility can be determined, preventing the possible harmful effects of galvanic corrosion. So, for example, choosing zinc on zinc would have the lowest risk for corrosion. ~ fe 2+ + 2e) and there are several possible cathodic reactions: Web to minimize galvanic corrosion, select fasteners based on their material compatibility with the substrates. This form of corrosion has the potential to attack junctions of metals, or regions where one construction Web the galvanic corrosion table ranks metals from the most “active” to the least active. This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a given metal coming into contact with another metal. Hydrogen evolution (acids) 2h + + 2e ~ h2. In this article, we'll look at an example to illustrate the use of the galvanic table. The list begins with the more active (anodic) metal and proceeds down.

The Following Galvanic Table Lists Metals In The Order Of Their Relative Activity In Seawater Environment.

Web read on to find out about what it is and how to use it to analyse the compatibility of joining metals. Web below is a galvanic reaction chart for dissimilar metals. Metals listed on the top of the chart (anodic) will corrode faster than the metals on the bottom of the chart (cathodic). Web in a galvanic couple, the metal higher in the series (or the smaller) represents the anode, and will corrode preferentially in the environment.

Web However, You Can Completely Avoid Galvanic Corrosion By Choosing Matching Metal Anchors.

Web there are two primary types of galvanic cells that cause corrosion: The list begins with the more active (anodic) metal and proceeds down. Use this chart below to better understand what metals will work best together without potential for galvanic corrosion: This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a given metal coming into contact with another metal.

The Corroded Area Was Machined Out And Rebuilt With Alloy 625 Filler Metal Which Is Cathodic To The Copper Nickel Piping.

Galvanic series / galvanic table. Web galvanic corrosion undermined the keeper rings, leading to failure and leakage. Web to minimize galvanic corrosion, select fasteners based on their material compatibility with the substrates. Web galvanic corrosion is a localised mechanism by which metals can be preferentially corroded.

The Closer Together The Material Are On The Chart To The Right, The Less Galvanic Action Will Occur.

Web in each solution, it is possible to establish a « galvanic series », i.e. The small surface area of the active bolts results in an undesirable galvanic couple and they are exhibiting an accelerated corrosion rate. Hydrogen evolution (acids) 2h + + 2e ~ h2. Web the galvanic corrosion table ranks metals from the most “active” to the least active.