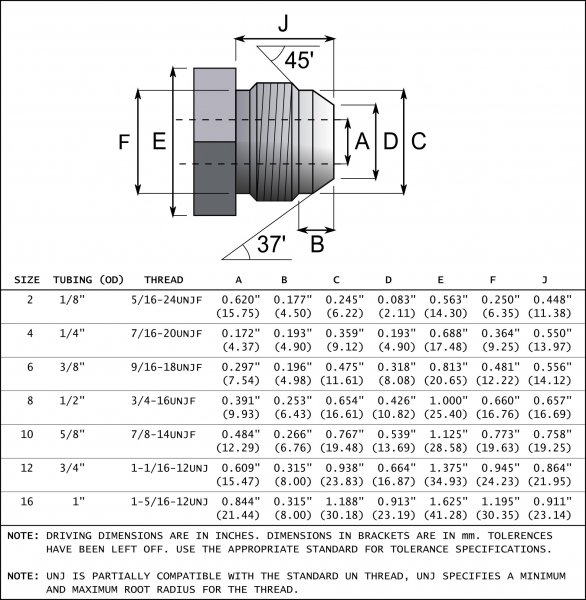

The only difference is komatsu uses millimeter thread sizes while jis use a bsp (british standard pipe) thread. The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Actional thread pitch gauge, a metric thread pitch gauge, th. The nut, the sleeve, and the fitting in a range of sizes f om 1/8” up to 2”. Sealing surface should be smooth.

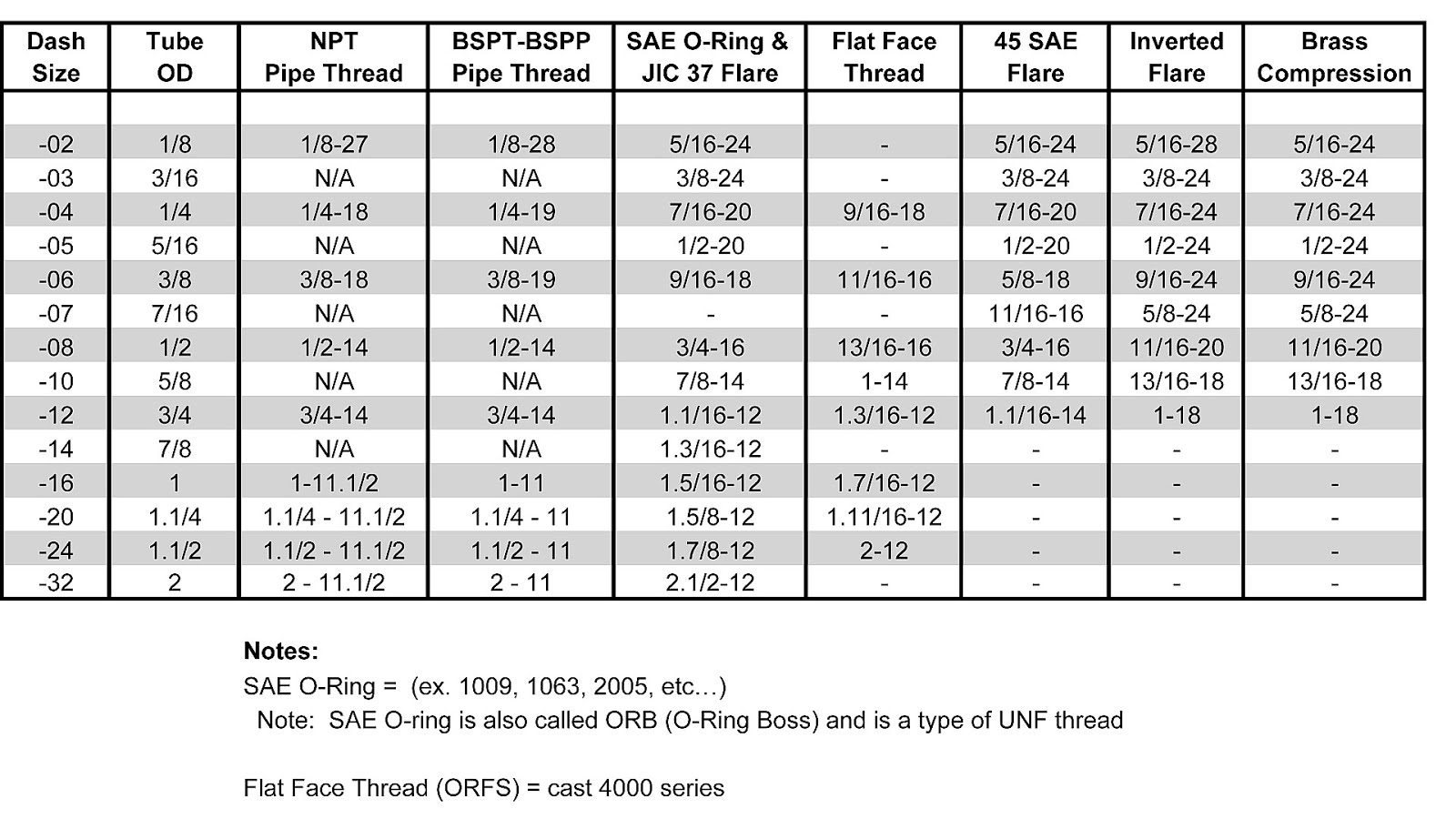

We also show the actual unf thread used on these fittings and how this will read in a digital vernier gauge. Web below we've compiled a hydraulic hose fittings chart describing some of the more common fitting sizes and types currently in use by pipefitters and other professionals. Thread identification guide to common threads including bsp, jic, orfs, metric, flanges and more from apex fluid power. Jic fitting systems have three components that make a. Web jic fittings come in various sizes, from 1/8 inch to 2 inches, and the thread size is expressed in inches.

Jic fitting systems have three components that make a. Annular tool marks of 100uin concentric with thread are permissible. Inspect for possible contamination or damage from shipping or handling. The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Simply click the links below to be taken direct to the thread identification for that type.

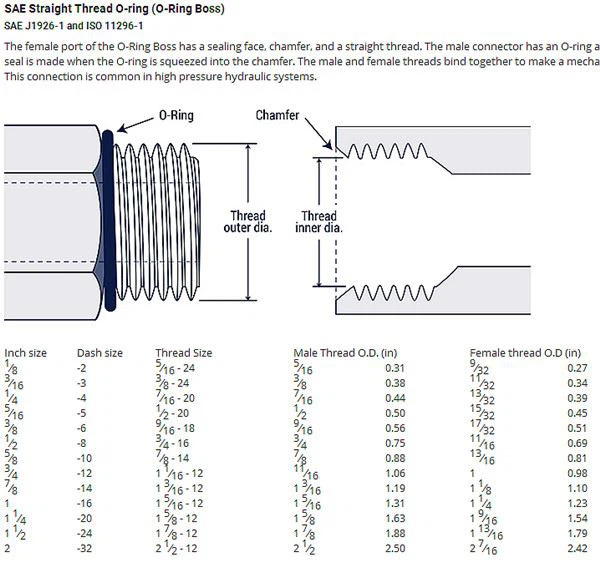

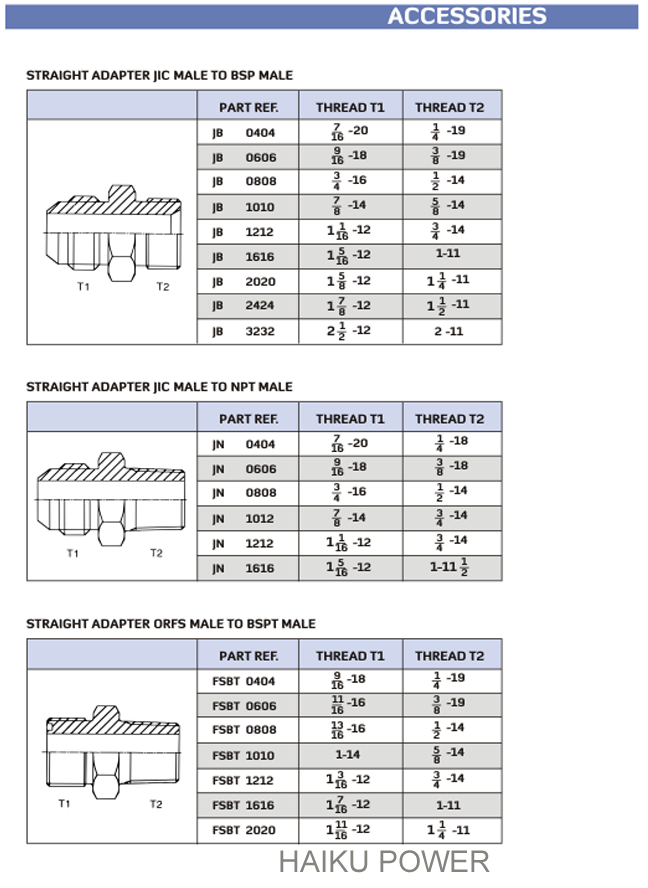

Jic fitting systems have three components that make a. When connected, the flare seats form a seal, while the straight threads provide a mechanical bond. Web 2) identify the fitting visually, using illustrations in the proper section of this manual; Annular tool marks of 100uin concentric with thread are permissible. Please contact us and we will get this to you asap. Web measure the thread diameter with an i.d./o.d. Thread dash for jic (37° flared) series 23 / 24 / p23 / p12 / p24 / p25 / 26 connectors. Web jic fittings size chart for identifying the correct size of bulkhead fitting adapter for skid steer quick couplers. Web both the jic male and jic female fittings have 37° seat with straight threads. Thread identification guide to common threads including bsp, jic, orfs, metric, flanges and more from apex fluid power. 4) compare measurements to the tables in this manual. Web the sizes are consistent with sae standard j514, making them interchangeable with fittings from different producers, as long as these adhere to the same standard. Jic fittings typically have unified national fine (unf) threads, while jis fittings have metric threads. Use a thread pitch gauge to determine the number of threads per inch or the distance between threads in metric connections. The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads.

Web Both The Jic Male And Jic Female Fittings Have 37° Seat With Straight Threads.

Thread dash for npt (dryseal taper) A carrying case is standard for easy a. Jic fitting systems have three components that make a. The seal takes place between the male flare and female cone seat.

Thread Dash For Jic (37° Flared) Series 23 / 24 / P23 / P12 / P24 / P25 / 26 Connectors.

The 37° jic connection consists of three pieces: Web the table below shows which an size matches which jic size. Web 2) identify the fitting visually, using illustrations in the proper section of this manual; To choose the thread size, you need to measure the male thread's outside diameter (od) or the female thread's inside diameter (id).

Web This Guide Features 28 Pages Of Helpful Information And Illustrations, Tips For Measuring & Identifying Common Threads, Visual Id And Size Guide For Multiple Fitting Types, And Thread Dimension Chart Covering 15 Different Thread Types.

We also show the actual unf thread used on these fittings and how this will read in a digital vernier gauge. We can also provide a pdf/hard copy for easy reference in the field. Actional thread pitch gauge, a metric thread pitch gauge, th. This means that jic fittings may require different tools and adapters than jis fittings when installing or repairing hydraulic systems.

When Connected, The Flare Seats Form A Seal, While The Straight Threads Provide A Mechanical Bond.

Web manufacturers use identifiers such as asme b1.1 and iso 261, to classify the main thread characteristics: Use a thread pitch gauge to determine the number of threads per inch or the distance between threads in metric connections. Lubricate the threads and the entire surface of the cone with hydraulic uid or a light lubricant. 3) measure id, od, thread pitch and seat angles using the proper tools;