Monolithic’s recommended procedure for splicing rebar has changed. The equation is.002 times the bar diameter times the allowable stress of the steel. Web we would like to show you a description here but the site won’t allow us. Learn the required overlap of lap splicing specified by building codes. Unless otherwise shown on the plans, the.

Monolithic’s recommended procedure for splicing rebar has changed. On the other hand, splice length is the length required to fully transfer the force from one bar to the adjacent bar. Web rebar development length calculator. The calculator returns the length of rebar lap in inches. Web we would like to show you a description here but the site won’t allow us.

In a tension lap, the force is transferred from the reinforcement bars to the concrete by the bond which in turn force back to the reinforcement. Web the rebar lapping length calculator computes the length overlap needed at rebar joints. Web we would like to show you a description here but the site won’t allow us. Reading the tables to find development/. However, this can be automatically converted into other length units (e.g.

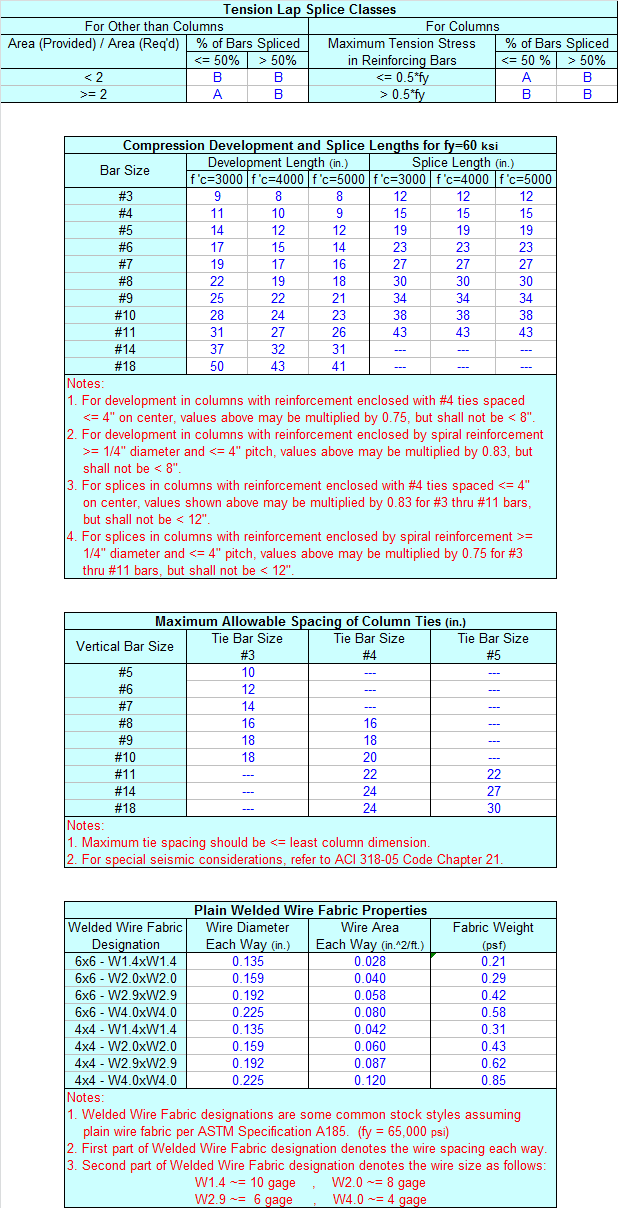

In fact, when i first started we overlapped and welded the bars together. Web tension lap splice length. Web the chart is for rebar laps and splices. Millimetres of lap related to number of bar diameters. Select wire/bar size to be developed/spliced: The length of the lap depends on the diameter of the bar and the type of steel. Of deformed bars or wires in tension. For residential construction, and as a general rule, logix recommends a lap length of 24” for horizontal reinforcment (vertical reinforcement should be continuous for the full *table based on uniform building code (icbo, 1997), section 1912.2.2. For years and years, we just overlapped the rebar and tied the bars together. Crsi’s reinforcement anchorage and splices includes tables of required lap splice lengths based on these variables. Web splice lengths are rounded up to the nearest inch. Lengths are in inches.= 3,000 psi to 5,000 psi notes: Divide by 1.3 for class a splices or for developent lengths of deformed bars in tension. Web the length of a lap splice varies with concrete strength, type of concrete, the yield strength (grade) of the reinforcing bars, bar size, bar spacing, concrete cover, and the amount of ties or stirrups.

Adhering To The Latest Aashto Standards, This Tool Ensures Accurate, Reliable Measurements For Optimal Structural Integrity.

Web the chart is for rebar laps and splices. The length of the lap depends on the diameter of the bar and the type of steel. Aci 318 provides tables with tabulated lap lengths based on bar diameter, concrete strength, and type of splice (standard, hooked, or welded). Number of bar diameters (using bar size) 10.

Web Rebar Development Length Calculator.

Web the length of a lap splice varies with concrete strength, type of concrete, the yield strength (grade) of the reinforcing bars, bar size, bar spacing, concrete cover, and the amount of ties or stirrups. In fact, when i first started we overlapped and welded the bars together. For years and years, we just overlapped the rebar and tied the bars together. Crsi’s reinforcement anchorage and splices includes tables of required lap splice lengths based on these variables.

Web The Rebar Lap Length Calculator Supports All Available Rebar Sizes And Concrete Strengths, Whilst Supporting Factoring For Reinforcement Bundling, Lightweight Concrete And Plain (Round) Bar Reinforcement.

On the other hand, splice length is the length required to fully transfer the force from one bar to the adjacent bar. In a tension lap, the force is transferred from the reinforcement bars to the concrete by the bond which in turn force back to the reinforcement. Web the length of the lap varies depend on concrete strength, the rebar grade, size, and spacing. Learn the required overlap of lap splicing specified by building codes.

For Residential Construction, And As A General Rule, Logix Recommends A Lap Length Of 24” For Horizontal Reinforcment (Vertical Reinforcement Should Be Continuous For The Full

Codes often specify minimum lap lengths regardless of. To stay with the codes, we use this chart for every project. D of deformed bars or wires in tension. Monolithic’s recommended procedure for splicing rebar has changed.