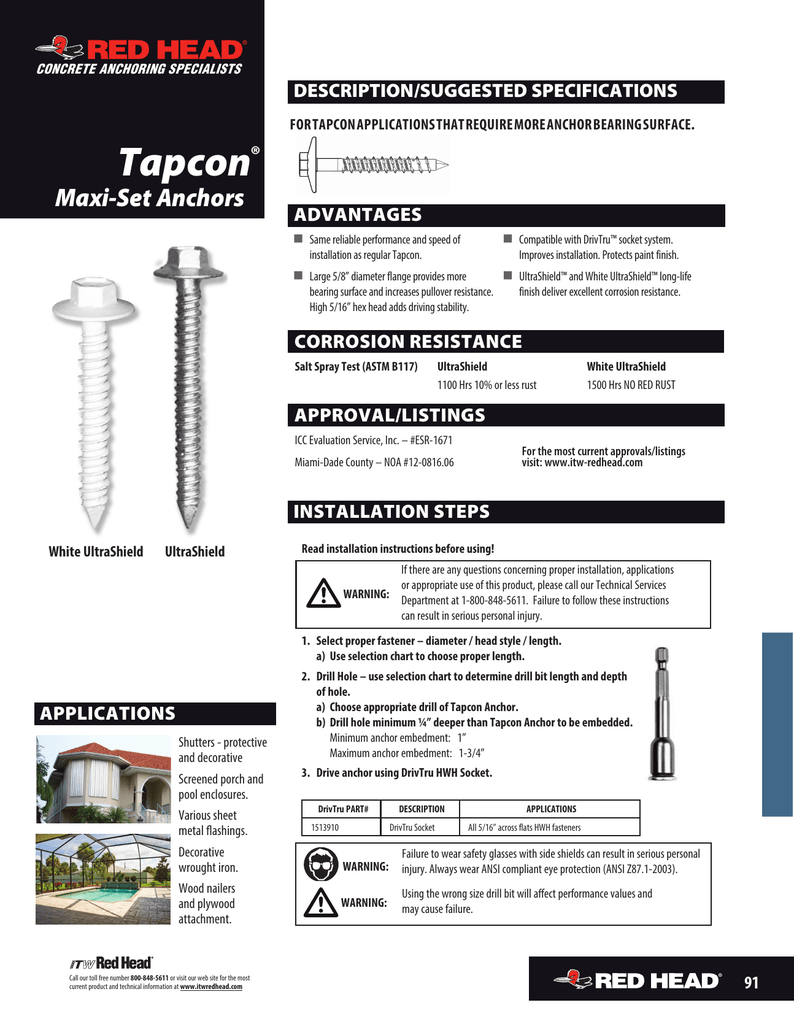

Use the tapcon bits and condrive pro together to install tapcon anchors for optimal performance. Select a length that meets your application needs. Onger than the necessary embedment.allowable loads are. Web tapcon concrete screw technical specifications and information. Tool drives 3/16” and 1/4” diameter tapcons.

Installs both head styles and all lengths of tapcons. Eliminates the need for two drills or extra nut drivers. The “original masonry” anchor that cuts its own threads into concrete, brick, or block. Web tapcon concrete screw technical specifications and information. Tool drives 3/16” and 1/4” diameter tapcons.

Web a safety factor of 4:1 or 25% of ultimate pullout/shear value is generally accepted as a safe working load. Designed for use with a hammer drill and tapcon drill bits. Installs both head styles and all lengths of tapcons. The “original masonry” anchor that cuts its own threads into concrete, brick, or block. Web makes installation of tapcon® concrete anchors easy, fast, and accurate.

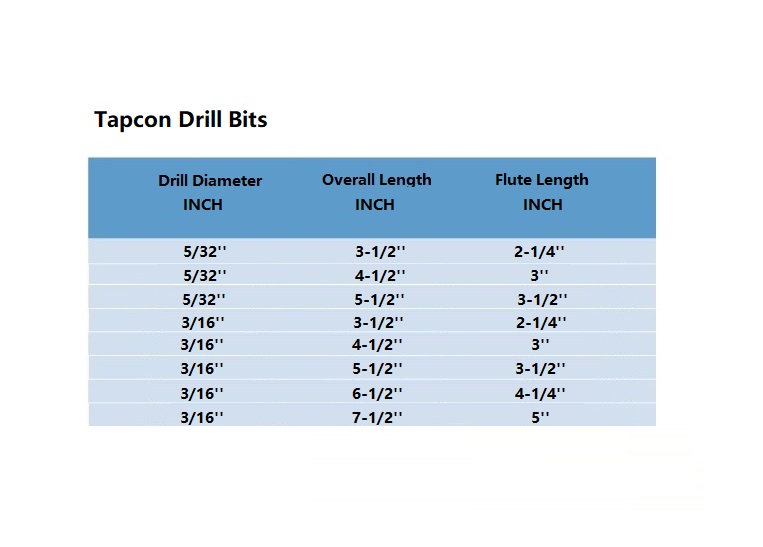

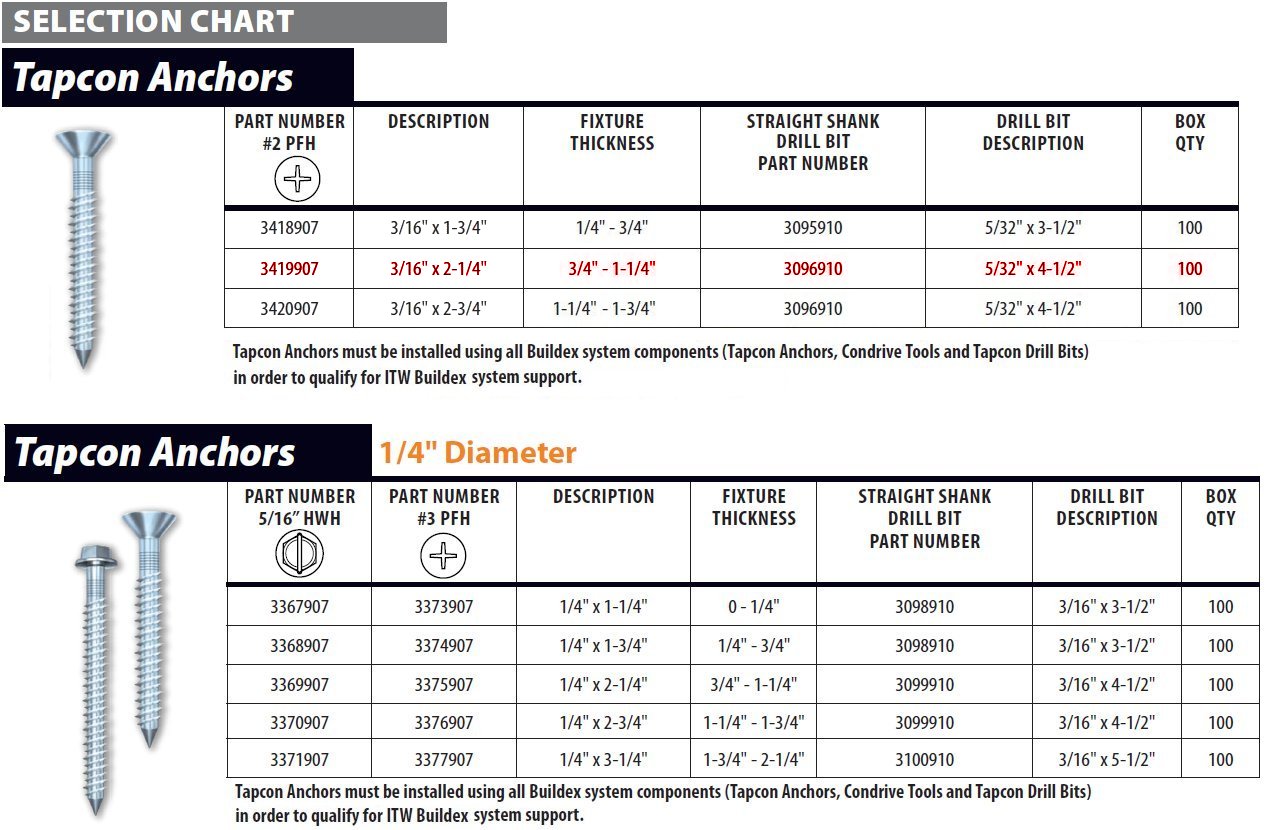

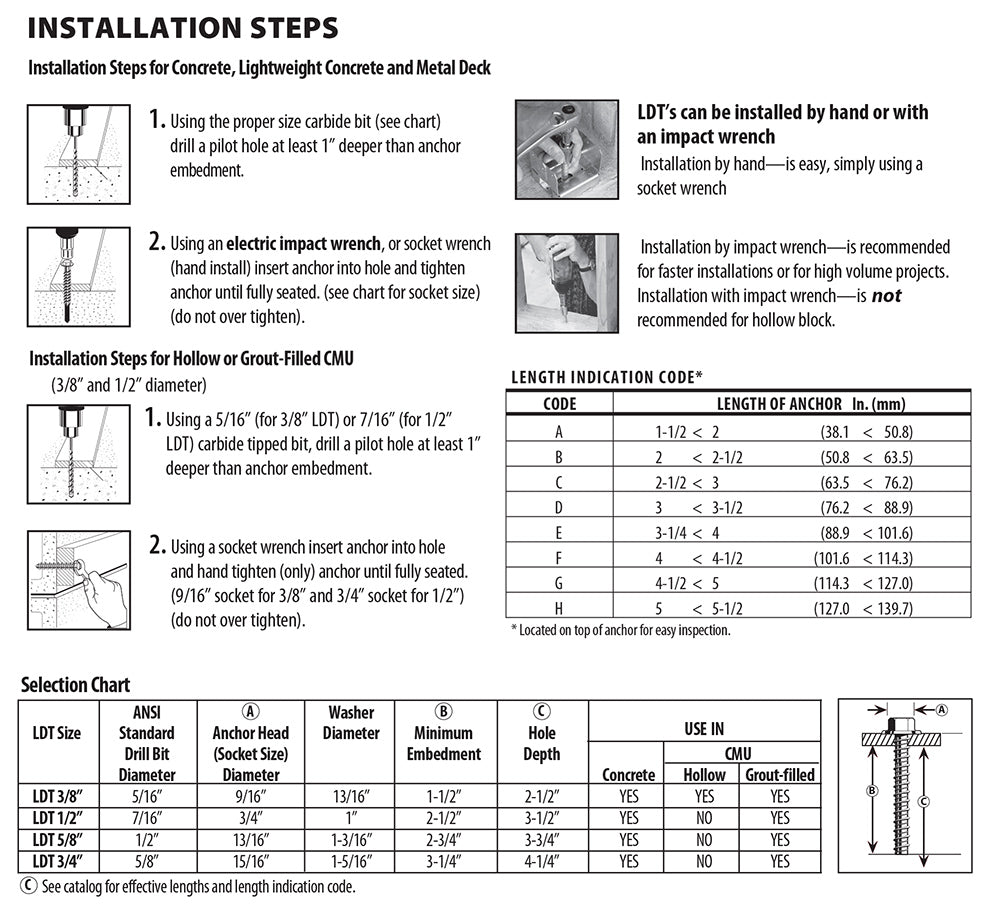

Designed for use with a hammer drill and tapcon drill bits. Web tapcon sds plus drill bits are specially designed to be compatible with condrive pro installation kit. Web the following charts show the diameter and length of the tapcon screw and the diameter and overall length of the carbide bit for the straight shank, sds, sds max, and spline bit. Approved for use in acq treated lumber. Installs both head styles and all lengths of tapcons. Eliminates the need for two drills or extra nut drivers. Divide by 4.pilot hole diameter shall be 0.263” and drilled 1/4”. Web a safety factor of 4:1 or 25% of ultimate pullout/shear value is generally accepted as a safe working load. It is essential to use the condrive tool and the correct drill bit to. Use the tapcon bits and condrive pro together to install tapcon anchors for optimal performance. The “original masonry” anchor that cuts its own threads into concrete, brick, or block. Web makes installation of tapcon® concrete anchors easy, fast, and accurate. Web genuine tapcon screw anchors. Maximum performance is achieved because the tapcon anchor, the condrive. For decades, tapcon ® products have enabled professionals to get the job done right the first time, every time.

Before Using The Products, All Specifications And Calculations Must Be Checked By A Suitably Qualified Person And Local Regulations Must Be Observed.

Web makes installation of tapcon® concrete anchors easy, fast, and accurate. Web the following charts show the diameter and length of the tapcon screw and the diameter and overall length of the carbide bit for the straight shank, sds, sds max, and spline bit. Web tapcon sds plus drill bits are specially designed to be compatible with condrive pro installation kit. Onger than the necessary embedment.allowable loads are.

Use The Tapcon Bits And Condrive Pro Together To Install Tapcon Anchors For Optimal Performance.

Holding values, size range, material specifications and values. Select a length that meets your application needs. For decades, tapcon ® products have enabled professionals to get the job done right the first time, every time. Installs both head styles and all lengths of tapcons.

Eliminates The Need For Two Drills Or Extra Nut Drivers.

Web tapcon concrete screw technical specifications and information. It is essential to use the condrive tool and the correct drill bit to. Web concrete anchors & tapcon drill bits | tapcon. Maximum performance is achieved because the tapcon anchor, the condrive.

The “Original Masonry” Anchor That Cuts Its Own Threads Into Concrete, Brick, Or Block.

Our concrete screw anchors deliver 30% less torque and 20% more holding power, while our drill bits make it possible to create precise holes at maximum power. Tool drives 3/16” and 1/4” diameter tapcons. Approved for use in acq treated lumber. Web a safety factor of 4:1 or 25% of ultimate pullout/shear value is generally accepted as a safe working load.