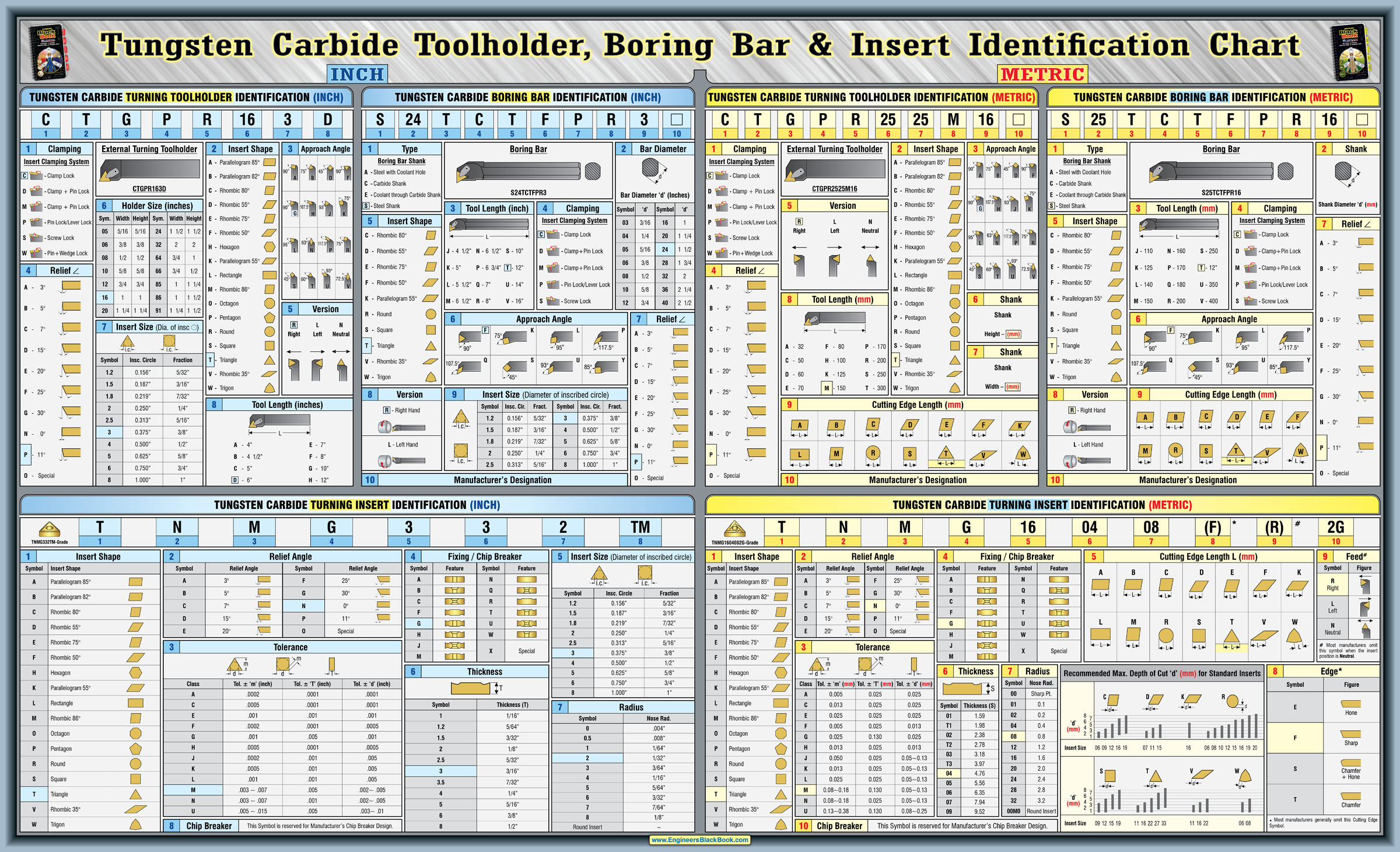

Web milling inserts and grades for hardened steel chevron_right. Web use this turning insert designation system guide to learn the name of the turning insert you need based on an existing inserts specifications, or as a handy reference guide that explains your inserts' specifications based on its name. Web this guide covers all the fundamental aspects you should consider when choosing the right carbide inserts. Web these tables show the ansi and iso insert designations for indexable inserts for turning. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition.

Web this guide covers all the fundamental aspects you should consider when choosing the right carbide inserts. Web carbide insert designation chart (printable pdf) view document. Learn more about carbide inserts, and how to buy the right carbide inserts online. Web kennametal first choice carbide grades for turning, milling, parting, and grooving. Web cbn and ceramic grades optimized for hard part turning.

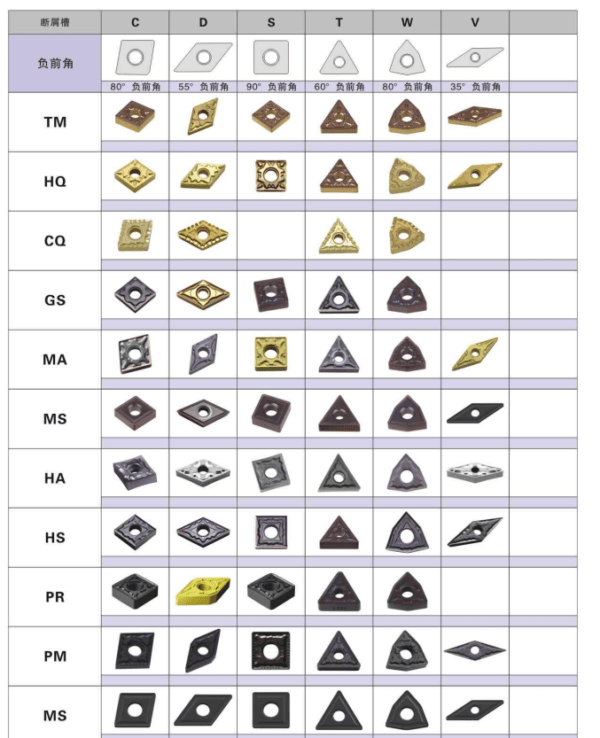

Web this guide covers all the fundamental aspects you should consider when choosing the right carbide inserts. Web cbn and ceramic grades optimized for hard part turning. Web milling inserts and grades for hardened steel chevron_right. Web in this article, we will provide a friendly yet comprehensive guide on how to read and interpret carbide insert charts, empowering you to make informed choices when selecting cutting tools for your machining needs. Web carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining performance.

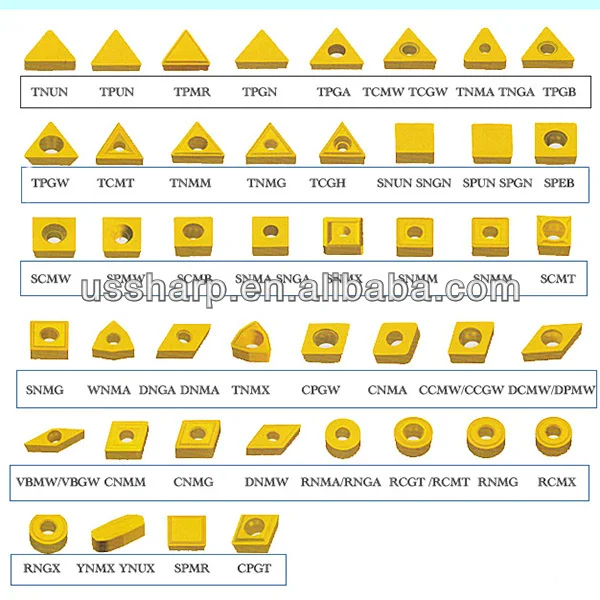

Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Including cutting speeds, compatible grades, application range, and more. A given insert can be specified in either ansi (american) or iso (metric) designations. Please choose a grade or geometry to find the kennametal equivalent. Web carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining performance. Select insert geometry based on selected operation, for example finishing. Web in this article, we will provide a friendly yet comprehensive guide on how to read and interpret carbide insert charts, empowering you to make informed choices when selecting cutting tools for your machining needs. Web milling inserts and grades for hardened steel chevron_right. Because many inserts are made in other countries, the iso system is used frequently. Web kennametal's competitive insert conversion guide can convert turning, holemaking and indexable milling grades or geometries, as well as solid carbide drilling and end milling grades. Web use this turning insert designation system guide to learn the name of the turning insert you need based on an existing inserts specifications, or as a handy reference guide that explains your inserts' specifications based on its name. Click the code letter or their description links in the example charts below for definitions of values: Web kennametal first choice carbide grades for turning, milling, parting, and grooving. Web engineers black book quick visual identification of carbide insert shapes. Web cbn and ceramic grades optimized for hard part turning.

Please Choose A Grade Or Geometry To Find The Kennametal Equivalent.

Web carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining performance. Learn more about carbide inserts, and how to buy the right carbide inserts online. A given insert can be specified in either ansi (american) or iso (metric) designations. Web carbide insert designation chart (printable pdf) view document.

Web Cbn And Ceramic Grades Optimized For Hard Part Turning.

Web this guide covers all the fundamental aspects you should consider when choosing the right carbide inserts. Web these tables show the ansi and iso insert designations for indexable inserts for turning. Web milling inserts and grades for hardened steel chevron_right. Because many inserts are made in other countries, the iso system is used frequently.

Learn How To Read The Ansi Insert Code System & Download A Free Carbide Insert Chart.

Web kennametal's competitive insert conversion guide can convert turning, holemaking and indexable milling grades or geometries, as well as solid carbide drilling and end milling grades. Select insert geometry based on selected operation, for example finishing. Web use this turning insert designation system guide to learn the name of the turning insert you need based on an existing inserts specifications, or as a handy reference guide that explains your inserts' specifications based on its name. Web detailed information on turning inserts identification.

Click The Code Letter Or Their Description Links In The Example Charts Below For Definitions Of Values:

Web iscar first choice carbide grades for turning, milling, parting, and grooving. Web kennametal first choice carbide grades for turning, milling, parting, and grooving. Web engineers black book quick visual identification of carbide insert shapes. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides, troubleshooting, and standards such as iso13399 is also presented.