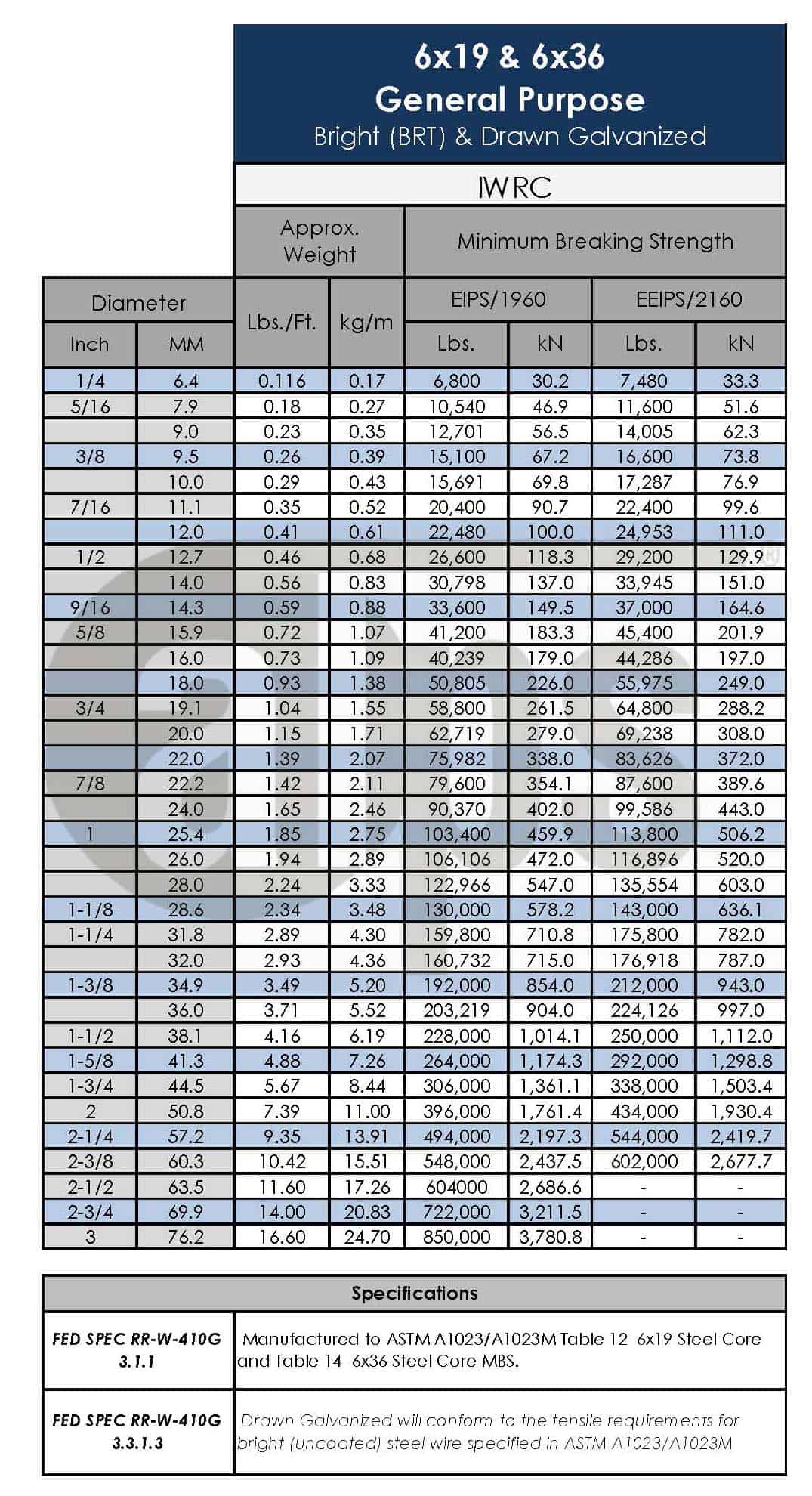

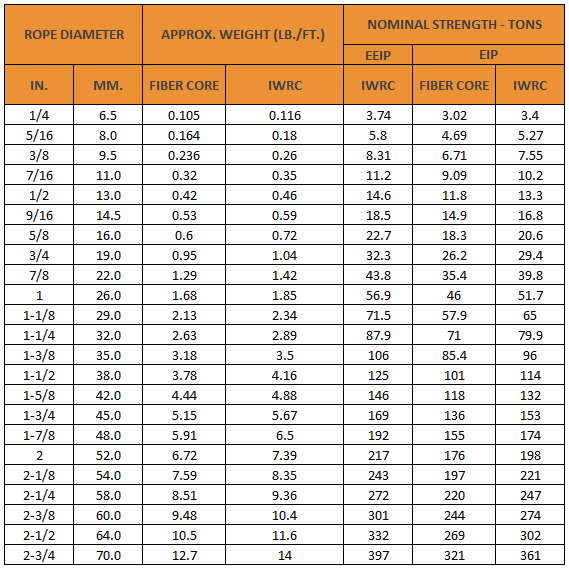

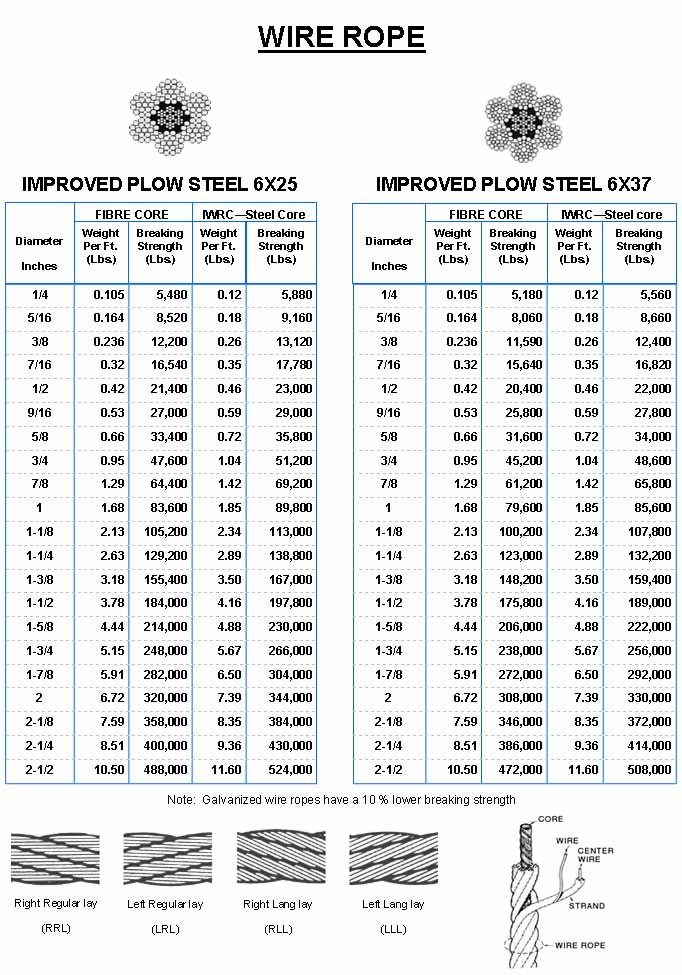

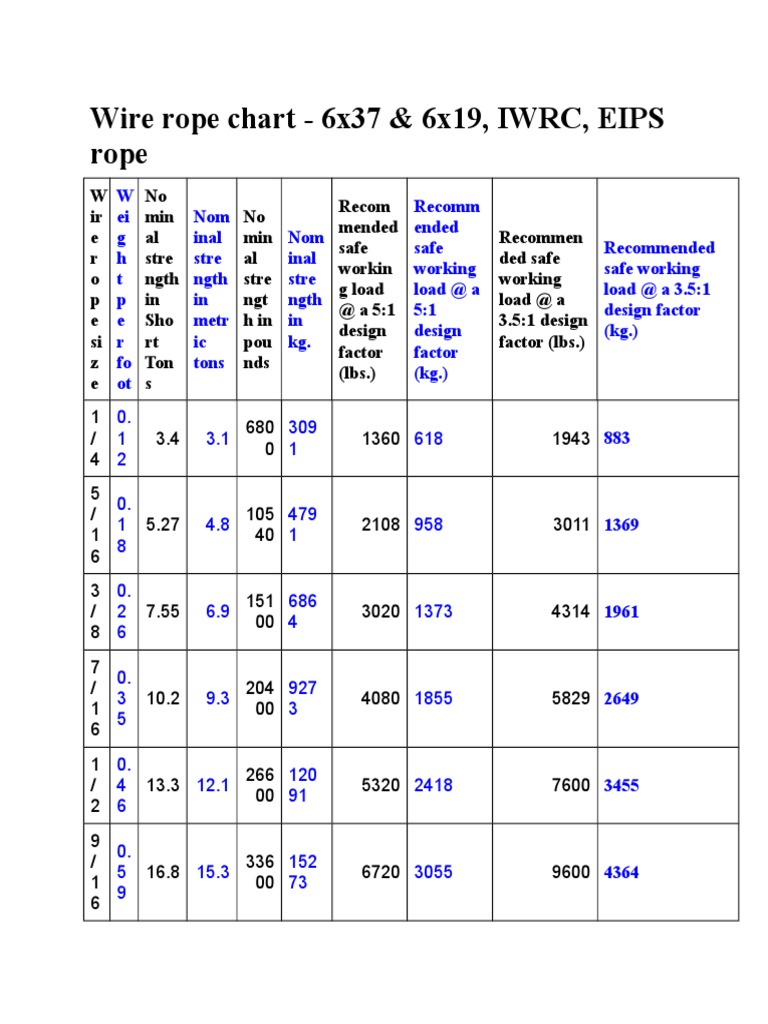

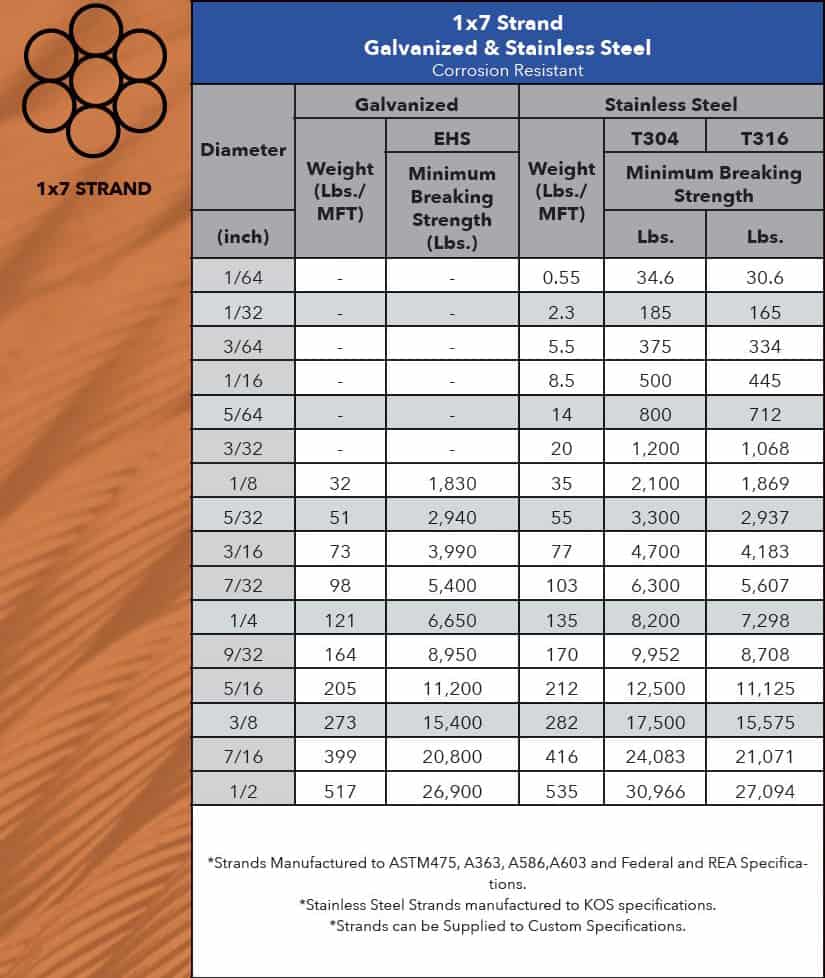

All ropes of the same size, grade and core offer somewhat similar minimum breaking force characteristics and weight per foot, though they do differ depending on the construction type and materials used. Web maximum safe mass for a 3/8 wire rope where the safe load is 10.9 kn can be calculated as. Download and print wire rope safe load chart. This article explores various types of wire ropes, their specific uses, and how to select the right one for your needs. Web different wire rope applications present varying demands for strength, abrasion & corrosion resistance.

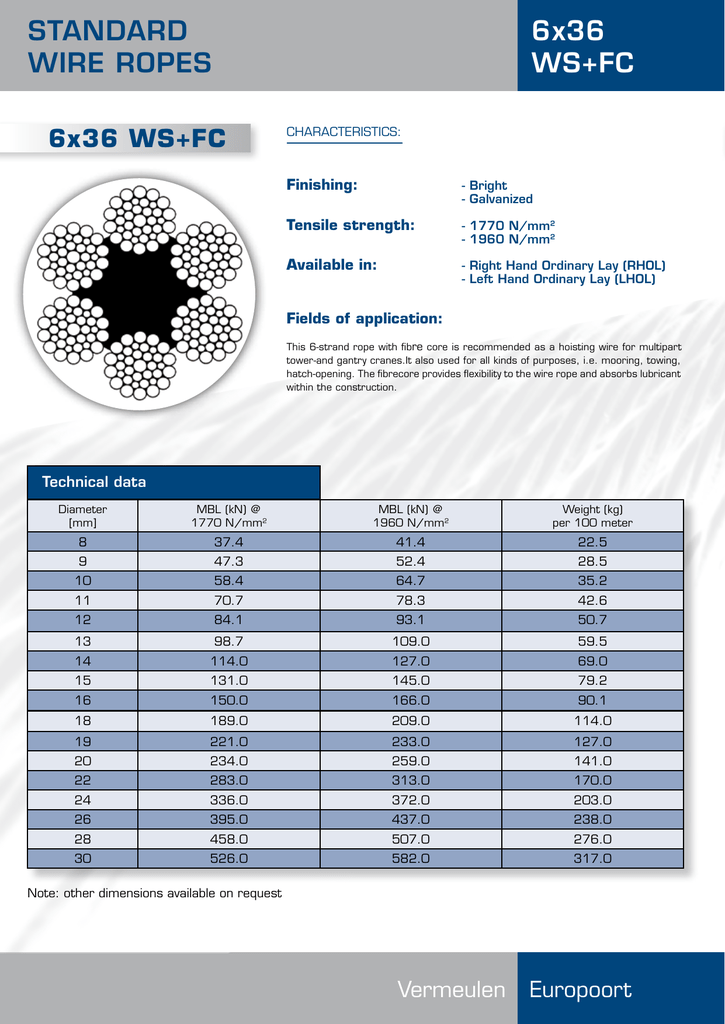

Web choices of wire ropes can be many. The first figure represents a brittle trend typical of high strength steel (over 2160 n/mm2). The rope’s construction is described by a designation like “6 × 17”. The following chart lists the size tolerances of wire rope. For example, a 1” diameter rope converts to 25.4 mm in metrics.

Web the graph below compares the behaviour of wires with different strengths: Using the soft conversion, this is changed to the whole metric size that most nearly parallels the 1” size range, or 26 mm. Our knowledgeable experts can help you determine what will work best whatever you’re doing. While 6 x 19 ropes have more abrasion resistance, the 6 x 36 ropes have more fatigue resi. Web wire rope, often called cable, is sized by diameter (not circumference, as large sizes of fiber rope are).

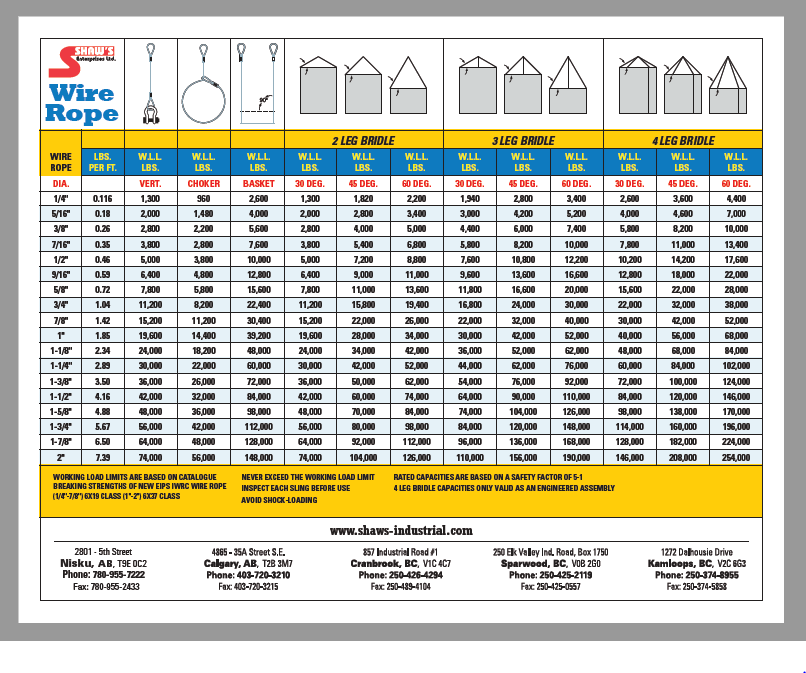

Web however, all wire ropes of the same size and wire grade in each classification will have the same strength and weight ratings and usually the same pricing. Web a simple wire rope strength chart can help you keep a close eye on wire rope strengths if find this to be an issue: 10” (sheave diameter) ratio a = 1/2” (wire rope diameter)= 20. All ropes of the same size, grade and core offer somewhat similar minimum breaking force characteristics and weight per foot, though they do differ depending on the construction type and materials used. M = (10.9 103 n) / (9.81 m/s2) = 1111 kg. Minimum breaking force and weights charts for 6x19, 6x36, powerflex, 3x19 and 3x36 ropes are included. The rope’s construction is described by a designation like “6 × 17”. Ropes include a combination of properties that give them specific performance abilities. Web what if a single component could transform the safety and efficiency of heavy lifting operations? Understanding these types and their inherent functions ensures optimal selection for targeted tasks. The table below shows some of the most common wire rope configurations arranged in specific classifications. The following chart lists the size tolerances of wire rope. This article explores various types of wire ropes, their specific uses, and how to select the right one for your needs. No single wire rope can do it all all wire ropes feature design property tradeoffs. Web choices of wire ropes can be many.

No Single Wire Rope Can Do It All All Wire Ropes Feature Design Property Tradeoffs.

Using the soft conversion, this is changed to the whole metric size that most nearly parallels the 1” size range, or 26 mm. They are so handy that you can easily either keep a printed copy or an image on your phone, allowing you to reference it at a moment’s notice. Web he same minimum breaking force, size for size. Web we stock all types of wire rope for every application from a truck winch or a pipe choker to a tugboat towing wire or crane rigging.

All Ropes Of The Same Size And Wire Grade In Each Classification Have The Same Strength And Weight Ratings, And Usually The Same Pricing.

Although their operating properties vary, all have the same weight per foot and the same minimum breaking force, size for size. Web rope diameter for standard, general purpose wire ropes, in measuring diameter, the industry is leaning toward a “soft” conversion to metric during the transition period. Learn more about wire rope & cable assemblies here. M = (10.9 103 n) / (9.81 m/s2) = 1111 kg.

Web Wire Rope, Often Called Cable, Is Sized By Diameter (Not Circumference, As Large Sizes Of Fiber Rope Are).

Wire ropes, often overlooked, are essential in construction, mining, and marine applications. How do you know which one works best for you? While the 6 x 19 ropes give primary important for their fatigue resistance. Web wire rope strength charts help you easily match the wire rope you need for your lift.

For Example, A 1” Diameter Rope Converts To 25.4 Mm In Metrics.

Web wire grades determine the wire rope strength and include improved plow steel (ips), extra improved plow steel (eips) for 15% more strength, or extra extra improved plow steel (eeips) for 10% more strength over eips. The following chart lists the size tolerances of wire rope. Ropes include a combination of properties that give them specific performance abilities. The second figure represents the typical trend of lower strength steel (1770 and 1960 n/mm2).